Description

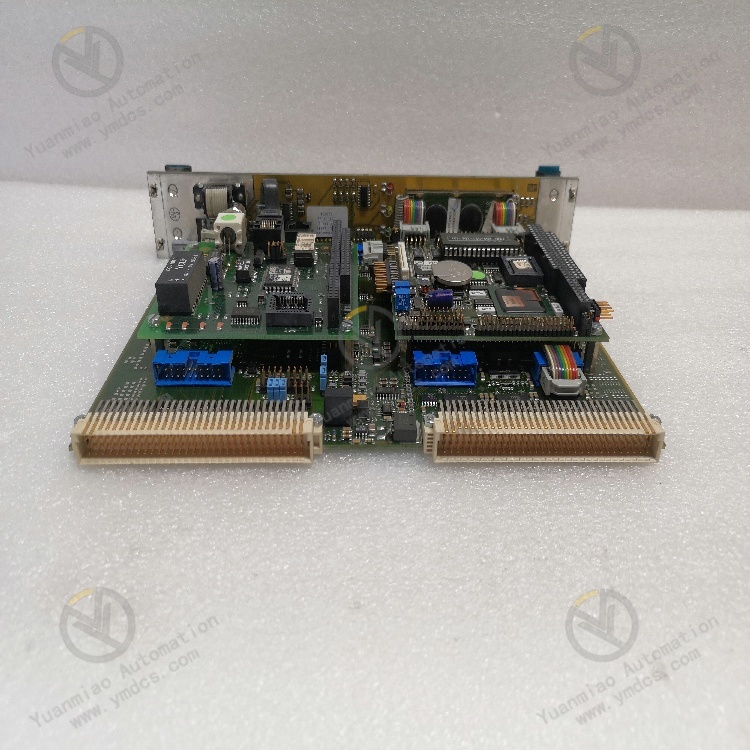

The Vibro-meter 200-595-031-111 VM600 CPUM is a control processor module in the VM600 series. Functional Positioning: It serves as the system controller and data communication gateway for the VM600 rack-based Mechanical Protection System (MPS) and/or Condition Monitoring System (CMS), and is used in conjunction with the IOCN modular input/output cards. Communication Capability: It supports communication protocols such as Modbus RTU/TCP or PROFINET. It can be connected via Ethernet or RS-232 serial interface to a computer running the VM600 MPSx software, enabling "one-time" configuration management of the protection cards (MPC4 and AMC8) in the VM600 rack.

Display and Operation: There is a display on the front panel, which is used to show the monitoring output and alarm limits of the protection cards. It is also equipped with a General Alarm Reset (AR) function to ensure the safety of the protection cards and the VM600 MPS rack (CPUM).

Event Logging: The VM600 system event and measurement event logs can be obtained through the VM600 MPSx software, which is convenient for users to trace back and analyze the system operation status.

In addition, the 200-595-031-111 VM600 CPUM adopts a modular design and has powerful data processing capabilities. It can be widely applied in fields such as industrial automation, process control, and mechanical equipment monitoring. It has a compact size, is easy to install, and has a reliable and stable power input.

The vibration measuring instrument VM600 may encounter various common faults during its operation. These faults may be caused by multiple factors such as sensor problems, signal transmission issues, hardware failures, software problems, etc. The following are some common faults: Sensor Faults: As a key component for obtaining vibration signals, the sensor may have various problems. For example, due to long-term use or external impacts, vibrations, etc., the sensitivity of the sensor may decrease, resulting in inaccurate measurement data. In a strong vibration environment, the internal sensitive elements of the acceleration sensor may be damaged, causing the measurement results to deviate from the actual values. In addition, the connection part of the sensor is also prone to looseness or damage, which leads to the abnormal transmission of signals and affects the accuracy of measurement.

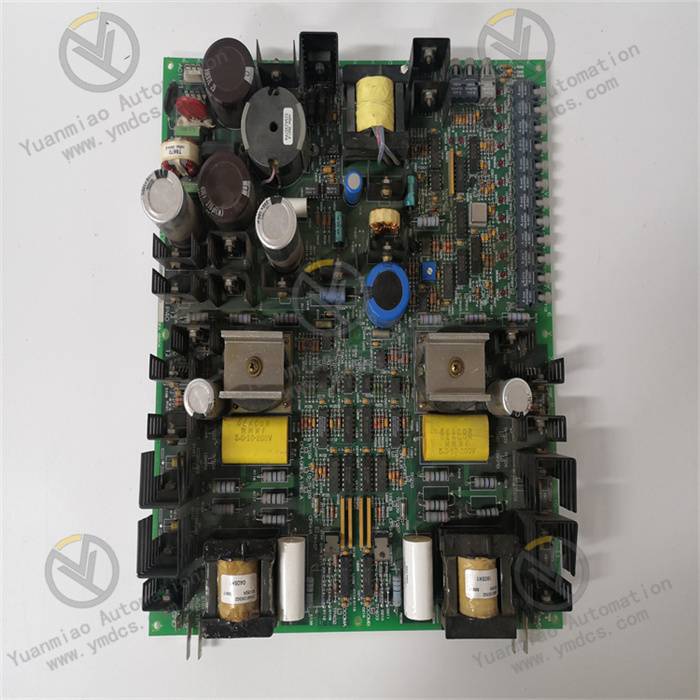

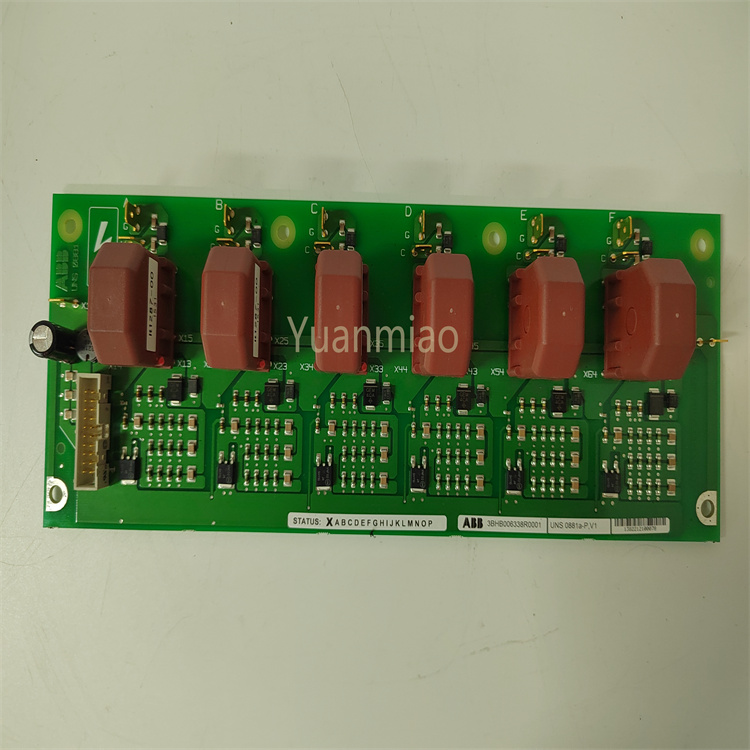

Signal Transmission Faults: The signal transmission line is the bridge connecting the sensor and the main body of the measuring instrument. If it is damaged or has poor contact, it will lead to the interruption or interference of signal transmission. For instance, after long-term use, the outer skin of the transmission line may be damaged, and the internal wires may break, affecting the normal transmission of signals. When the joint of the signal transmission line is not firmly connected, contact resistance will be generated, resulting in signal attenuation or distortion, and making the signals received by the measuring instrument inaccurate. Moreover, in an environment with strong electromagnetic interference, signal transmission may also be affected, generating noise and thus interfering with the measurement results. Hardware Failures: The internal hardware components of the measuring instrument may also malfunction. For example, the electronic components on the circuit board may be damaged due to aging, overheating, or other reasons, causing the measuring instrument to fail to work properly. When key components such as the processor chip and memory have faults, it may lead to problems such as the measuring instrument freezing, failing to boot up, or incorrect data processing. If the power module of the measuring instrument malfunctions, such as unstable output voltage, power short circuit, etc., it will also affect the normal operation of the measuring instrument.

Software Failures: The software system of the VM600 may encounter various problems during its operation. For example, there may be bugs or errors in the software, resulting in abnormal display or analysis of measurement data. If there are errors during the software update process, it may cause the system to fail to start up normally or lack certain functions. Compatibility issues between the software and hardware may also cause the measuring instrument to fail to work properly, such as the software being unable to recognize the hardware device or unable to correctly read the sensor data.

Parameter Setting Errors: When users use the measuring instrument, if the parameters are not set correctly, it will also lead to inaccurate measurement results or the abnormal operation of the measuring instrument. For example, improper settings of parameters such as the measurement range, sampling frequency, and filtering parameters may cause the measurement data to fail to reflect the actual vibration situation. If the user sets the measurement range too small, when the actual vibration value exceeds this range, the measuring instrument may not be able to measure accurately and may even damage the sensor.

Calibration Problems: The vibration measuring instrument needs to be calibrated regularly to ensure the accuracy of measurement. If it has not been calibrated for a long time or the calibration method is incorrect, the measurement results of the measuring instrument may deviate. Inaccurate standard instruments used during the calibration process will also lead to inaccurate calibration results, thus affecting the normal use of the measuring instrument.

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:https://www.ymdcs.com/Vibro-meter/