Description

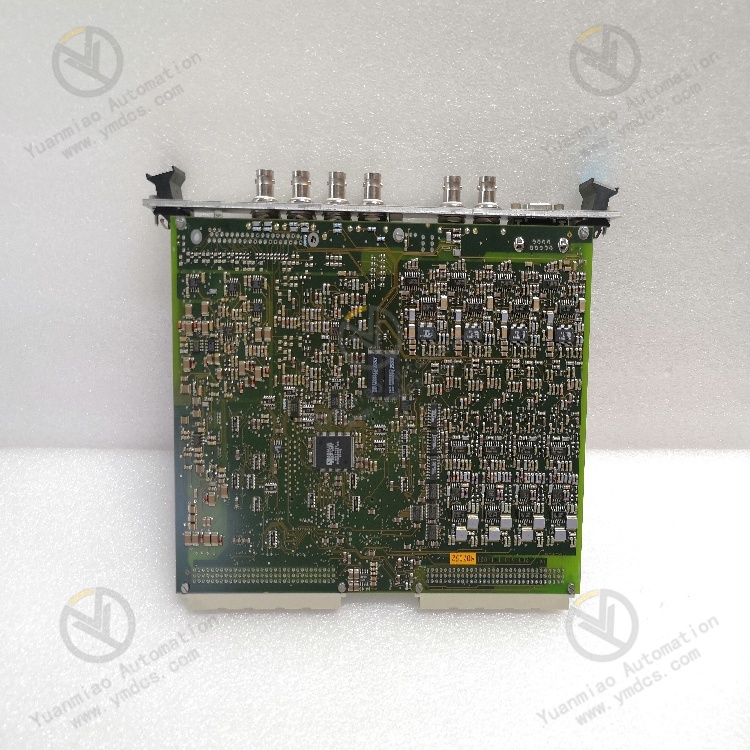

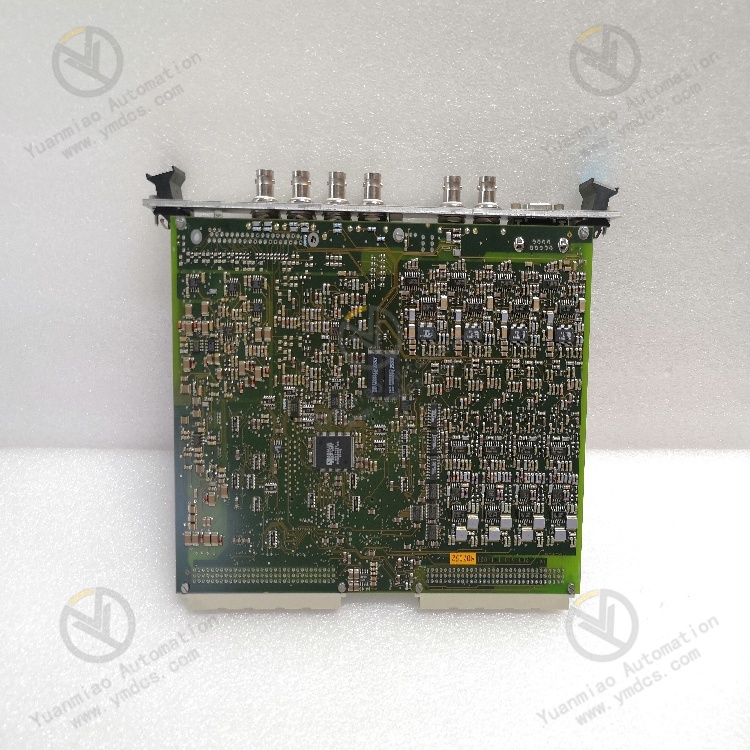

The Vibro-meter 200-510-041-021 and 200-510-111-021 are component numbers or configuration codes related to the VM600 MPC4 mechanical protection card. The VM600 MPC4 is the core module in the VM600 system for vibration monitoring and protection of mechanical equipment.

Chnnel Configuration: It provides 4 dynamic channels and 2 tachometer (speed) channels. All channels can be configured independently, and it can monitor multiple vibration channels and speed channels simultaneously to have a comprehensive understanding of the vibration status of the equipment.

Signal Processing: It adopts advanced DSP technology, high-precision sensors, and advanced algorithms, featuring high measurement accuracy and strong reliability. It is equipped with programmable broadband and narrowband filters, which can filter the input signals according to different measurement requirements and equipment characteristics, eliminating noise interference and extracting useful vibration information. It can automatically diagnose various mechanical faults such as unbalance, misalignment, looseness, and bearing faults, and provide accurate early warning information.

Alarm Function: It supports programmable alarm, danger, and judgment setpoints, as well as adaptive alarm and danger levels. When the vibration value of the equipment exceeds the preset threshold, it can issue an alarm in a timely manner to remind the operators to take measures. It can also adaptively adjust the alarm and danger levels according to the operating conditions and historical data of the equipment, improving the accuracy and reliability of the alarm.

Communication Capability: It supports multiple communication protocols such as RS-232, RS-485, and Modbus, making it convenient to communicate with host computers, DCS/PLC systems, etc., and enabling remote data transmission and monitoring. The measurement data and equipment status information can be transmitted to the monitoring center in real time, facilitating remote monitoring and management.

Hardware Characteristics: It supports real-time plugging and unplugging (hot swapping) and executes self-check and diagnostic programs when powered on, which is convenient for installation, debugging, and maintenance. It is designed with sturdy materials and can withstand harsh industrial environments such as high temperature, humidity, and vibration, ensuring stable operation under demanding conditions. It provides "Standard", "Independent Circuit", and "Safety" (SIL) versions. Both the "Standard" and "Safety" (SIL) versions have passed the IEC 61508 and ISO 13849 certifications and can be used in functional safety environments.

Display and Operation: The front panel is usually equipped with a display for showing information such as the monitoring output and alarm limits of the protection card, which is convenient for the operators to intuitively understand the equipment status. At the same time, function keys such as the General Alarm Reset (AR) are provided, which is convenient for operation and control.

As a powerful mechanical protection card, the VM600 MPC4, with its high-precision vibration monitoring and analysis capabilities, has a wide and important application in many fields that require ensuring the stable operation of mechanical equipment. The following are some of the main application scenarios:

Power Industry: In power production sites such as thermal power plants, hydropower plants, and nuclear power plants, there are a large number of rotating mechanical equipment, such as steam turbines, generators, fans, and water pumps. The VM600 MPC4 can monitor the vibration status of these equipment in real time, promptly detect abnormal vibrations caused by reasons such as unbalance, misalignment, and bearing wear, prevent shutdown accidents caused by equipment failures, and ensure the stable supply of electricity. For example, through the precise monitoring of the vibration of the steam turbine, potential problems such as blade damage can be detected in advance, avoiding the occurrence of major equipment accidents.

Petrochemical Industry: In the petrochemical production process, many large and complex mechanical equipment are involved, such as compressors, reactor agitators, and pumps. These equipment operate in harsh environments such as high temperature, high pressure, and corrosion, and equipment failures may lead to serious safety accidents and production interruptions. The VM600 MPC4 can continuously monitor the vibration of the equipment, conduct comprehensive analysis in combination with other process parameters, and promptly detect early failure signs of the equipment, such as compressor surging and pump cavitation, providing an accurate basis for the maintenance and repair of the equipment and ensuring the safety and stability of the production process.

Metallurgical Industry: In metallurgical enterprises such as iron and steel and non-ferrous metals, the normal operation of various mechanical equipment such as rolling mills, blast furnace fans, and continuous casters is of great importance. The VM600 MPC4 can monitor and analyze the vibration of these equipment in real time, helping enterprises to promptly discover problems such as equipment wear and looseness, optimize the operating status of the equipment, improve production efficiency, and reduce equipment maintenance costs. For example, by monitoring the vibration of the rolling mill, the rolling parameters can be adjusted in a timely manner to improve the quality of the steel.

Mechanical Manufacturing Industry: In the mechanical manufacturing process, the vibration status of precision equipment such as numerically controlled machine tools and machining centers directly affects the machining accuracy and quality of products. The VM600 MPC4 can accurately measure and analyze the vibration of these equipment, helping enterprises to optimize the machining process and improve the machining accuracy and stability of the equipment. At the same time, for the assembly and debugging process of large mechanical equipment, the VM600 MPC4 can also be used for vibration monitoring to ensure the installation quality of the equipment.

Aerospace Industry: The reliability and safety of key components such as aircraft engines and aircraft landing gear are crucial for the aerospace industry. The VM600 MPC4 can be used for vibration monitoring and fault diagnosis of these components. Through the analysis of vibration signals, potential problems such as component wear and cracks can be detected in a timely manner to ensure the safe operation of aerospace equipment. For example, during the ground tests and flight processes of aircraft engines, the vibration status of the engines is monitored in real time, providing data support for the maintenance and improvement of the engines.

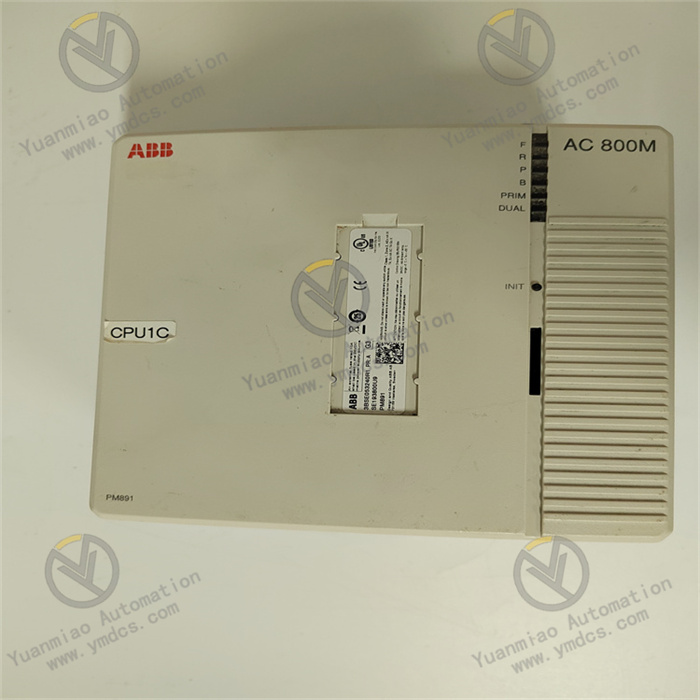

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

【 Disclaimer 】

We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.

This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:https://www.ymdcs.com/Vibro-meter/

![]()