Description

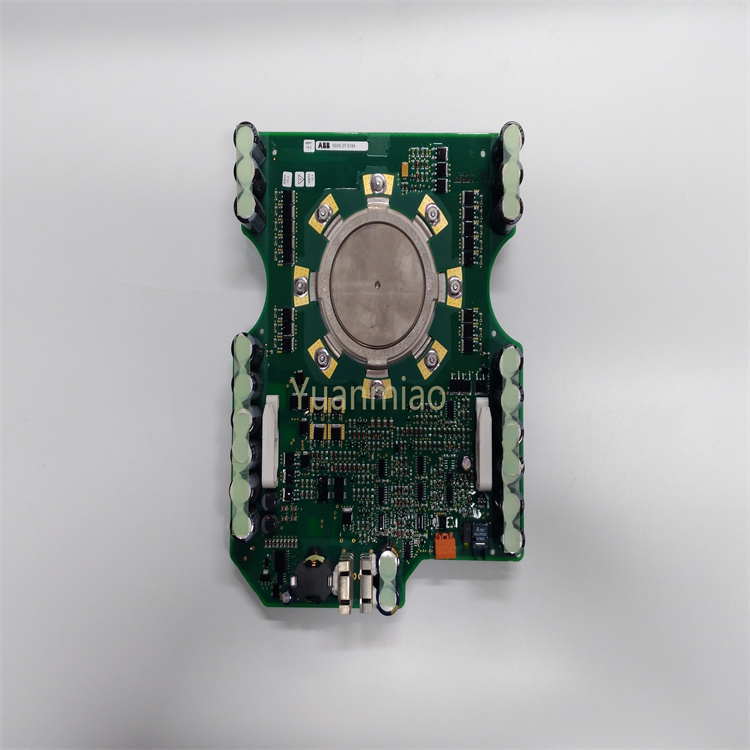

TEL TVB6002-1/IMC is an industrial control module, which is usually used in the field of industrial automation. TEL TVB6002-1/IMC 1308-644857-12: Basic Information: This is a high-performance industrial control module, specifically designed for precise process automation and control systems. The product number is TVB6002-1/IMC 1308-644857-12, the brand is TEL, and it belongs to the type of PLC control board. Physical Characteristics: The dimensions are 30cm x 20cm x 5cm, and the weight is 1.2kg. Electrical Characteristics: The operating voltage is 24VDC, with 16 input channels and 16 output channels. Environmental Adaptability: The operating temperature range is from -20°C to +70°C, the storage temperature range is from -30°C to +80°C, and the humidity range is from 5% to 95% (non-condensing). Certification: It has passed certifications such as CE, UL, and ROHS, ensuring that it complies with relevant safety and quality standards and can operate stably and reliably in various industrial environments. This control board has a compact design, is suitable for application scenarios with limited space, and has a wide input voltage range, which can be compatible with various power supplies. It also supports multiple output voltages to meet different operating requirements. In addition, it is designed with advanced circuit protection functions, which can withstand harsh conditions and protect the connected equipment from electrical surges.

TEL TVB6002-1/IMC 1381-644857-16:

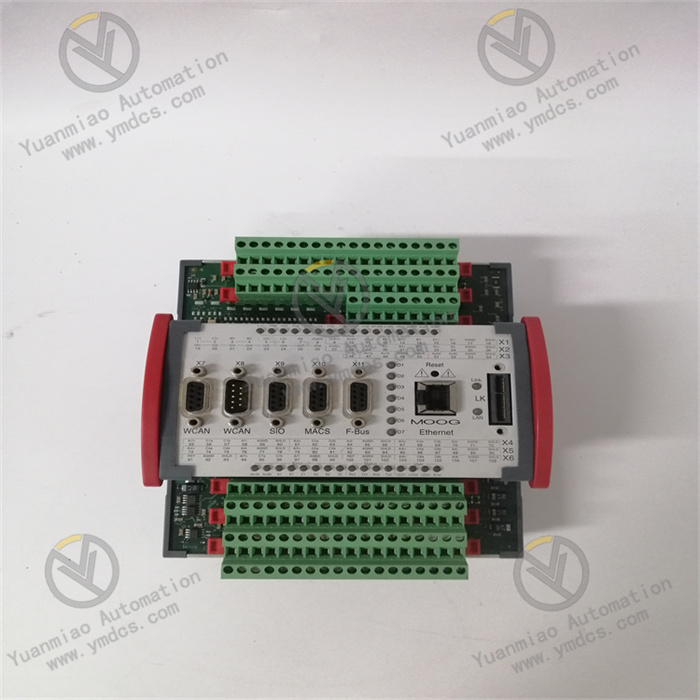

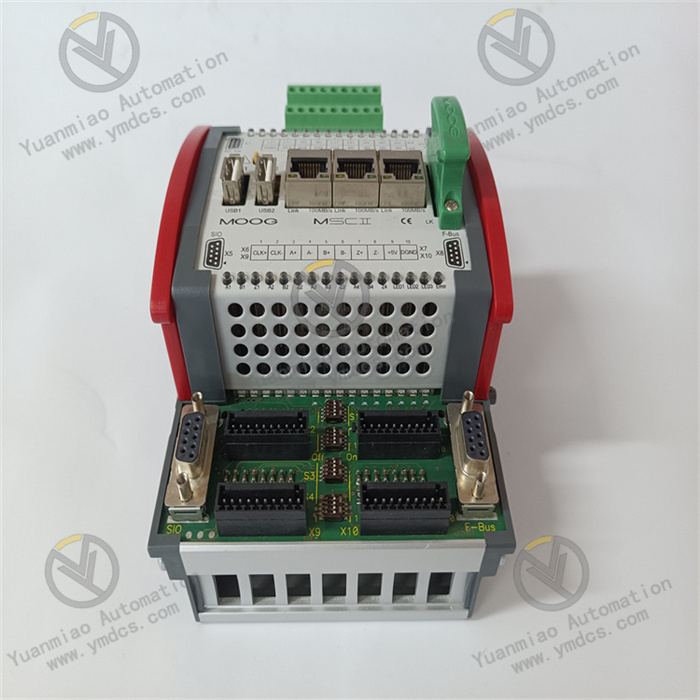

Module Type: It is an industrial programmable logic controller (PLC) module, suitable for advanced automation applications.

Functional Features: It provides reliable control and monitoring capabilities for various industries. It adopts advanced technology and can be seamlessly integrated into existing automation systems, making it an indispensable component for modern industrial applications. This module has a sturdy design and flexible and diverse communication protocols, ensuring smooth operation even under extreme conditions. Its compact shape and lightweight design make installation easy, and it can be flexibly placed in a narrow space without affecting its performance. In addition, it supports Modbus and Ethernet/IP protocols, providing flexibility and scalability for the expansion of industrial networks. It is a reliable and efficient choice whether for upgrading existing facilities or designing new control systems.

The TEL TVB6002-1/IMC module is typically a type of module in the field of industrial control. Its working principle mainly includes the following aspects: Input Signal Acquisition: Through the input interface connected to external devices, it collects status signals from external devices such as sensors, buttons, and switches. These signals can reflect various parameters in the production process, such as physical quantities like temperature, pressure, flow, and position, or they can be information about the operating status of the equipment, such as the start - stop status of motors and the open - close status of valves. After the input signals are processed by optocoupler isolation, filtering, etc., they are converted into digital signals for processing by the central processing unit (CPU) inside the module.

Signal Processing and Logical Operations: The CPU inside the module performs operations such as judgment and calculation on the collected input signals according to the pre - written program logic. The program logic is written based on specific industrial control tasks and can include various logical operations, mathematical operations, data processing algorithms, etc., to achieve precise control and management of the production process. For example, based on the signal input from the temperature sensor, the output power of the heating or cooling equipment to be adjusted is calculated through the PID control algorithm; or based on the combination of multiple switch signals, it is judged whether the equipment is in normal operating status, and corresponding alarm processing is carried out.

Output Signal Control: The control instructions processed by the CPU are sent to the output module. The output module converts these instructions into corresponding physical signals, such as voltage, current, and pulses, to control the working status of external actuators connected to the output end, such as motors, solenoid valves, relays, and indicator lights. For example, the rotation speed or start - stop of the motor is adjusted by controlling the output signal of the motor driver; the flow of fluid is controlled by controlling the on - off of the solenoid valve; the on - off of the circuit is realized by controlling the contact closure of the relay, thereby controlling the operation of various devices.

Feedback Signal Acquisition and Processing: To achieve more precise control and system stability, some TEL TVB6002 - 1/IMC modules also collect feedback signals of the working status of external actuators. These feedback signals can be the actual operating parameters of the actuators, such as the rotation speed feedback of the motor and the opening feedback of the valve, or they can be signals reflecting the operating status of the equipment, such as the fault alarm signal of the equipment. The module inputs these feedback signals for internal processing and analysis, compares them with the set target values, and adjusts the control strategy according to the deviation to form a closed - loop control system, ensuring that the production process can operate according to the expected goals.

Cyclic Scanning Working Mode: The TEL TVB6002 - 1/IMC module usually adopts a cyclic scanning working method, continuously repeating the processes of input signal acquisition, signal processing, output signal control, and feedback signal acquisition mentioned above. In each scanning cycle, the module sequentially collects and processes all input signals, then generates corresponding output signals according to the program logic, and updates the output status. This cyclic scanning working mode enables the module to monitor and control the industrial production process in real - time, respond promptly to changes in external signals, and ensure the stability and reliability of the system.

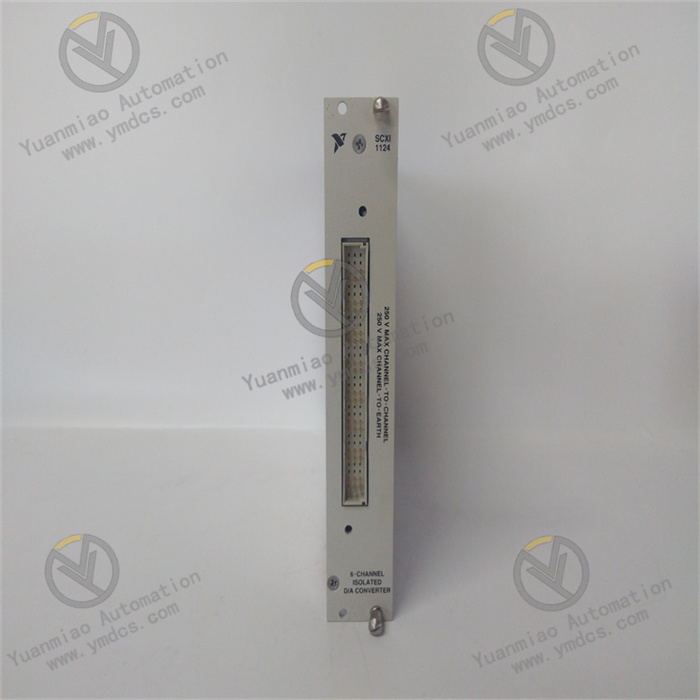

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.