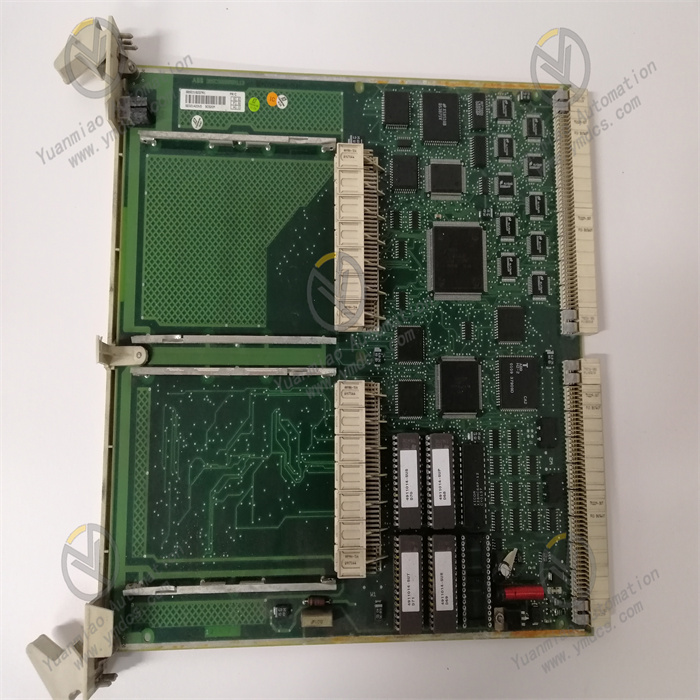

Description

WINGREEN FAN_DETECTION V1.0_A05 03ZSTJ3 - 00 - 105 is a PLC system board card for industrial control equipment. Electrical Characteristics: The operating voltage may be 220V. The output types include analog, digital, I2C, SPI, etc. The output frequency may be 510. The analog output range may be 4 - 20mA. The bus circuit requirement may be 480 milliamps, and the width is 4.1mm.

Hardware Features Rich Interfaces: It may be equipped with an Ethernet interface for high-speed data transmission, which can communicate with the host computer, server, or other intelligent devices to achieve remote monitoring and data interaction. It may also have serial interfaces such as RS - 485 and RS - 232, which are used to connect traditional industrial devices or nearby devices. It also has dedicated input and output interfaces, which are used to connect various sensors and actuators to achieve the collection of industrial field parameters and the control of equipment. Strong Processing Capacity: It has a high-performance microprocessor or controller built-in, with certain data processing and logical operation capabilities. It can quickly process the collected data, and conduct analysis and judgment according to the preset programs or algorithms, and then output control signals. Complete Storage Function: It has a certain capacity of memory or storage chip, which is used to store the equipment configuration information, operating programs, and collected data, etc., to ensure that the equipment can return to the correct working state after a power outage or restart.

Working Principle Data Collection: Through the connected sensors, it can collect relevant physical quantity data in the industrial field in real time, such as temperature, pressure, flow rate, liquid level, etc., and convert the analog signals into digital signals. Data Processing and Analysis: Transmit the collected data to the processor, and process and analyze it according to the preset algorithms and logic to determine whether the operation status of the industrial process is normal and whether control measures need to be taken. Control Output: If the analysis results indicate that control operations are required, the equipment will send control signals to the actuators through the output interfaces, such as controlling the start and stop of the motor, adjusting the opening degree of the valve, etc., to achieve precise control of the industrial process. Communication Function: It communicates with other devices or systems through the Ethernet or serial interface, uploads the collected data and the operation status information of the equipment to the monitoring system or host computer, and at the same time receives the control instructions and parameter settings from the host computer to achieve remote monitoring and management.

Performance Characteristics

High Reliability: Using high-quality electronic components and advanced manufacturing processes, and after strict testing and verification, it has strong anti-interference ability and can work stably and reliably in harsh industrial environments.

Good Flexibility: With rich interfaces and configurable parameters, users can flexibly adjust the functions and working modes of the equipment according to actual needs to adapt to different industrial control application scenarios.

Strong Real-time Performance: It can quickly respond to external events and control instructions, collect and process data in real time, ensure the timely control of the industrial process, and improve production efficiency and product quality.

Application Scenarios

Industrial Automation Production Lines: It is used to control the operation of various devices on the production line, coordinate the work of each process, realize the automation and intelligence of the production process, and improve production efficiency and product quality.

Process Control Field: In the production processes of industries such as chemical, pharmaceutical, and food and beverage, it precisely controls and monitors process parameters such as temperature, pressure, flow rate, and liquid level to ensure the stability of the production process and the consistency of product quality.

Energy Management System: In the energy fields such as power plants, substations, oil and gas extraction, and transportation, it is used to monitor and control the energy production and supply process to achieve the efficient use of energy and the safe and stable operation of the system.

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.