Description

Features

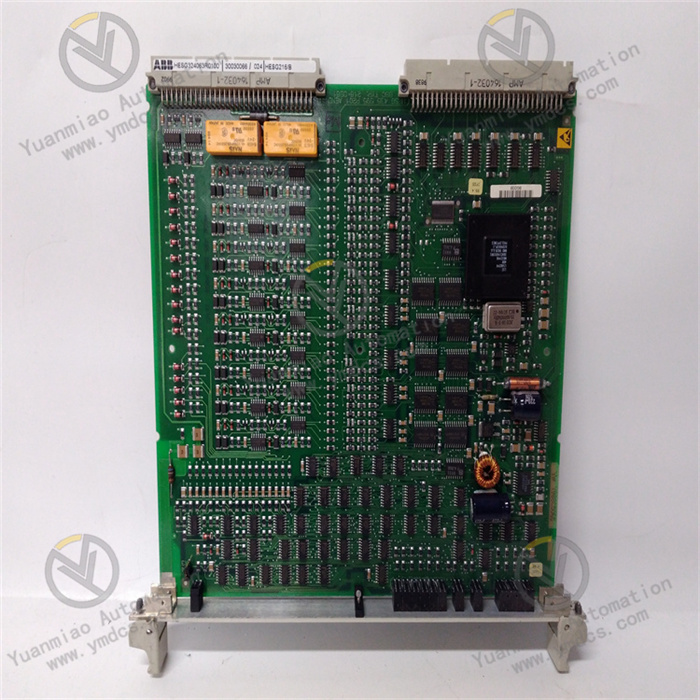

Unique Design: It adopts a hash design to simulate the CAM function, balancing speed, memory size, and cost, and can maintain high-efficiency performance when processing a large amount of data.

Rich Interfaces: It supports multiple interface protocols and can be seamlessly connected to different types of devices to achieve rapid data transmission and sharing.

Strong Processing Capability: It has a powerful data processing capability and can process and analyze the received data in real time, providing an accurate basis for decision-making in industrial production.

Functions Data Transmission and Sharing: Connect the P2 adapter board or LCP2 adapter board with the MVME162 backplane connector P2, providing interfaces for the EIA-232-D serial port, SCSI port, as well as other peripheral devices or LAN Ethernet ports, to achieve data transmission and sharing among different devices. Data Processing: Process and analyze the received data in real time to provide support for decision-making in industrial production.

Technical Parameters

Interface: 64bit/66MHz PCI interface.

Storage: Supports RAID levels 0, 1, 4, 5, and 10, with the functions of online RAID level migration and capacity expansion without the need for a reboot, and supports array roaming; there is a battery backup unit that provides backup power for the memory for up to 72 hours. The subsystem has 64MB of installed SDRAM and supports 64 - 256MB of ECC SDRAM.

Others: 2 channels of Ultra160 SCSI, with a transmission rate of up to 160 megabytes per second per channel; operating voltage is 230V; output frequency is AF100; protection level is IP65.

Application Areas Industrial Automation: Monitor and control the equipment on the production line to achieve the automation and intelligence of the production process. Data Acquisition and Monitoring System: Collect production data in real time and process it, providing strong support for enterprise production management and decision-making.

Application Scenarios Monitoring of Industrial Automation Production Lines: In the production lines of automobile manufacturing plants, the METSO IOP353 can be used to connect various automated devices, such as robot controllers, controllers of conveyor systems, welding equipment, etc. Through its multiple interface protocols, rapid data transmission and sharing among these devices are realized, enabling the operating status of the entire production line to be monitored and analyzed in real time. For example, when a certain robot malfunctions or the parameters of a certain production process are abnormal, the IOP353 can quickly transmit the relevant data to the central control system, so that engineers can take timely measures for adjustment and repair to ensure the efficient and stable operation of the production line. Data Acquisition and Analysis of Power Systems: In power plants, this module can be used to collect the operating data of various power equipment, such as the status information of generators, transformers, switchgear, and current and voltage data, etc. It is connected to the power monitoring system at high speed through the 64bit/66MHz PCI interface, and the collected data is processed and analyzed in real time. For example, parameters such as the output power of the generator and the voltage stability are monitored. When abnormal fluctuations are detected, early warning signals are sent out in a timely manner to help operation and maintenance personnel carry out maintenance and repairs in advance, prevent the occurrence of power failures, and ensure the safe and reliable power supply of the power system. Chemical Process Control Systems: In the chemical production process, the METSO IOP353 can be used to connect various sensors and actuators to achieve precise control and monitoring of equipment such as chemical reactors, distillation columns, and pipelines. By collecting analog signals such as temperature, pressure, flow rate, and liquid level, and converting them into digital signals for processing, and at the same time sending control commands to the actuators according to the control algorithm to adjust the valve opening, the rotational speed of the pump, etc., to ensure that the chemical production process proceeds in a safe and stable state, improve product quality and production efficiency, and reduce energy consumption and environmental pollution.

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.