Description

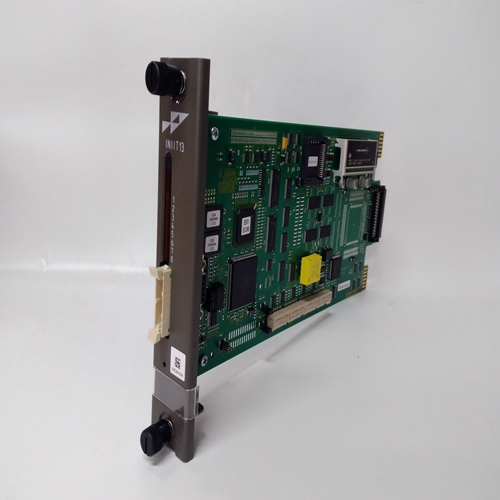

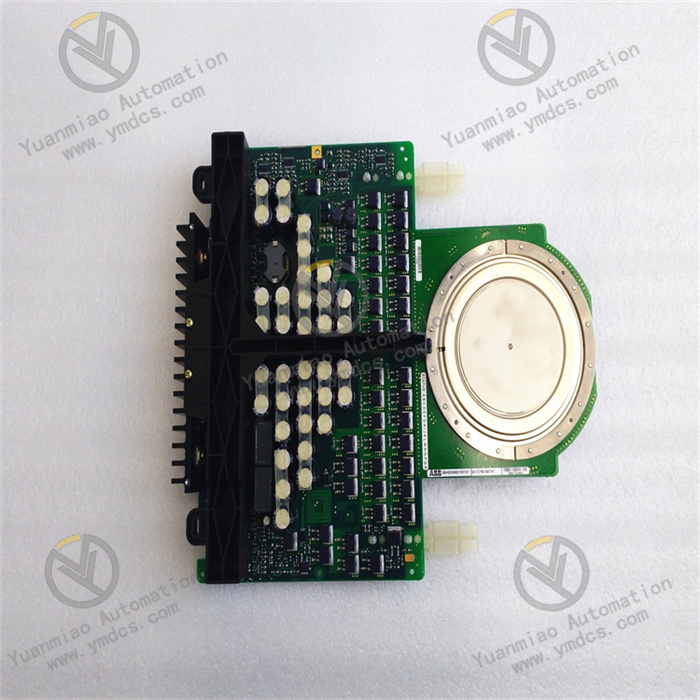

The METSO PDP403S is a module with specific functions produced by Metso. It may belong to the Distributed Processing Unit (DPU) series and is used in industrial automation control systems to monitor, control, and process data of various industrial processes.

Features

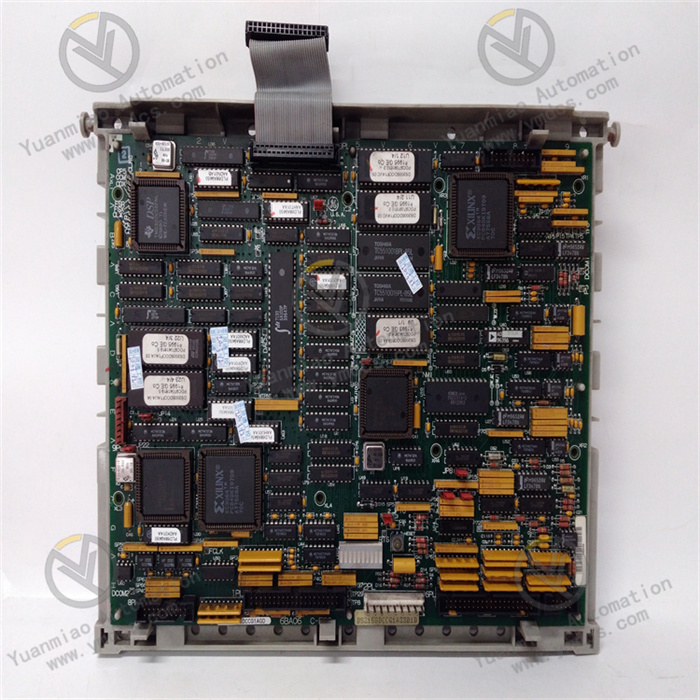

High-performance processing capability: It can quickly process a large number of input signals and data, enabling real-time monitoring and control of industrial processes and ensuring the efficient operation of the system.

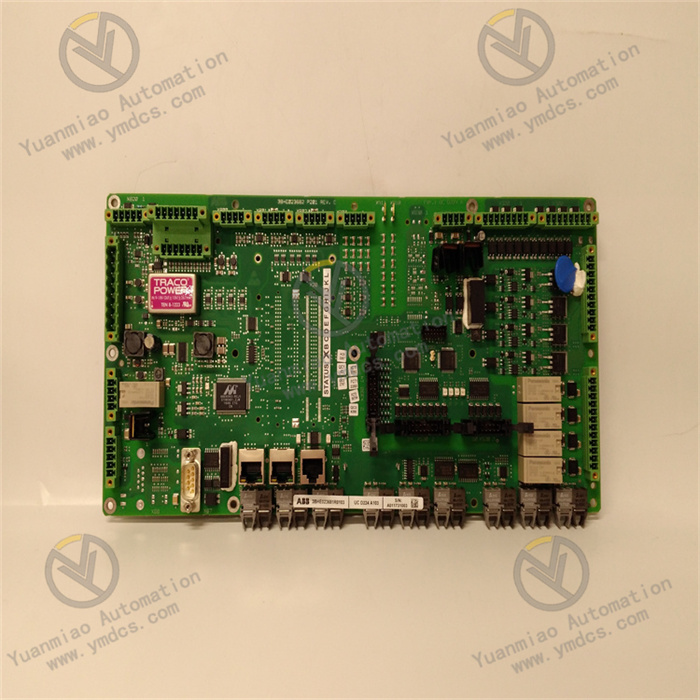

Rich interface types: Equipped with various communication interfaces, such as Ethernet, serial ports, Profibus DP, etc., it is convenient to connect with other devices and systems and interact data, and can be seamlessly integrated into various industrial automation networks.

Multi-channel design: With multiple input and output channels, it can connect multiple sensors and actuators simultaneously to meet the needs of collecting and controlling multiple signals in complex industrial systems.

High reliability: Complying with industrial standards, it uses high-quality electronic components and advanced manufacturing processes, has good stability and durability, and can operate stably for a long time in harsh industrial environments. It may also have functions of fault diagnosis and self-protection, such as the fault detection of input signals and the safety protection of output signals, which can effectively avoid system shutdown or damage caused by faults.

Flexible programming: It supports multiple programming methods, such as LD (Ladder Diagram), FBD (Function Block Diagram), IL (Instruction List), etc. Users can select appropriate programming methods according to their own technical level and project requirements, and conveniently write control programs to achieve various complex control logics.

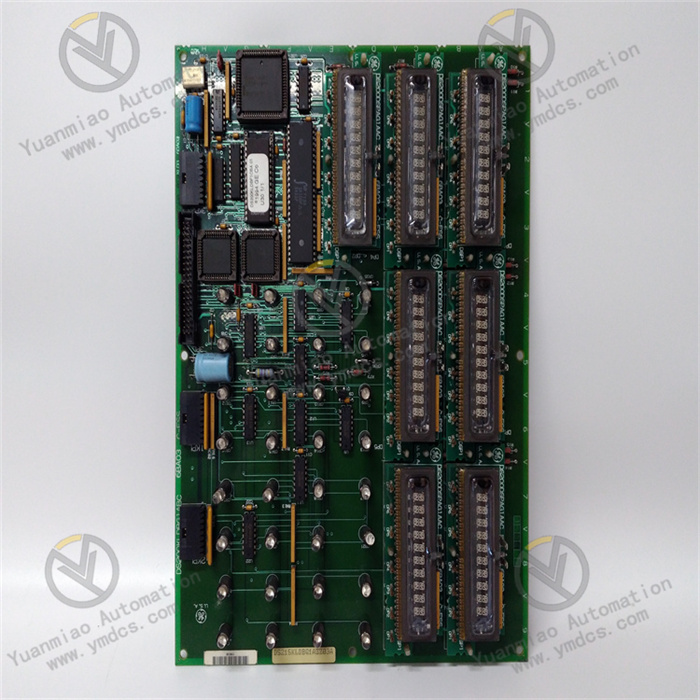

Functions Signal acquisition and processing: It can receive analog signals (such as temperature, pressure, flow rate, etc.) and digital signals from various sensors, condition, convert, analyze and process these signals, and convert them into data formats that can be recognized and processed by the control system. Control function: According to the preset control strategies and algorithms, it calculates and judges the processed data, and then sends control signals to the actuators through the output channels to achieve precise control of various devices in the industrial process, such as adjusting the valve opening, motor speed, switch status, etc., to ensure that the industrial process operates according to the expected goals. Data communication: With the help of its rich communication interfaces, it exchanges and communicates data with other devices or systems. It can upload the collected data to the upper computer monitoring system so that operators can know the running status of the industrial process in real time; at the same time, it can also receive instructions from the upper computer or other control systems to achieve remote monitoring and centralized management.

Technical Parameters

Input voltage: Usually 24VDC, which is suitable for the DC power supply in the industrial field.

Output signals: May include 4 - 20mA current signals, digital signals, etc., used to drive different types of actuators.

Communication protocols: Supports common industrial communication protocols such as Modbus RTU and Profibus DP to ensure compatibility and interoperability with other devices.

Interface type: Such as a 64bit/66MHz PCI interface, which can achieve high-speed data transmission and system expansion.

Storage: Supports RAID levels 0, 1, 4, 5, 10, has the functions of online RAID level migration and capacity expansion without the need for a reboot, and guarantees the security and reliability of data. Equipped with a battery backup unit, it provides backup power for the memory for up to 72 hours. The subsystem has 64MB of installed SDRAM and supports 64 - 256MB of ECC SDRAM.

Operating temperature: Generally -40℃ - 85℃, which can adapt to a wide range of temperature changes in industrial environments.

Application Areas

Industrial automation production lines: Used in various production lines such as automobile manufacturing and electronic device production, it monitors and controls the operation of equipment on the production line to achieve the automation, high efficiency, and quality control of the production process.

Power systems: In power facilities such as power plants and substations, it collects the operation data of power equipment, such as the status information and electrical parameters of generators, transformers, switchgear, etc., conducts real-time monitoring and analysis, and guarantees the safe and stable operation of the power system.

Chemical process control: Applied to the chemical production process, it connects various sensors and actuators, precisely controls and monitors equipment such as chemical reactors, distillation columns, and pipelines, ensures that the chemical production process proceeds in a safe and stable state, improves product quality and production efficiency, and reduces energy consumption and environmental pollution.

Other industrial fields: It can also be used in many industrial fields such as metallurgy, building materials, papermaking, water treatment, etc., to achieve the automation control and optimized management of industrial processes.

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.