Description

High-precision Input: It can accurately receive analog signals. Within the temperature range from 0°C to 60°C, the precision can reach below 0.15% of the full scale range (FSR), providing accurate input data for the system.

Strong Anti-interference Ability: It can operate stably in various complex industrial environments, effectively resisting electromagnetic interference and others, ensuring the stability and accuracy of signal transmission.

Flexible Input Range: It supports voltage inputs of 0 to 5 VDC or -5 to +5 VDC, meeting the output signal requirements of different field devices.

High Number of Input Points: It has 32 differential, DC-coupled input points, which can connect to multiple analog signal sources simultaneously, increasing the input capacity of the system.

Fast Input Update Rate: The input update rate is 10ms, which can promptly respond to the changes of analog signals and quickly convert the signals into digital signals for the system to process.

High Resolution: The resolution is programmable at 12 bits or 14 bits and can be adjusted according to actual needs to meet applications with different precision requirements.

Good Common Mode Rejection: The common mode rejection can reach -85 dB (DC–100 Hz), which can effectively suppress common mode interference and improve the quality of the signals.

Input Over-range Protection: It has the function of continuous input over-range protection of 150 VDC/115 VAC, which can prevent the module from being damaged due to excessive input signals, enhancing the reliability and durability of the module.

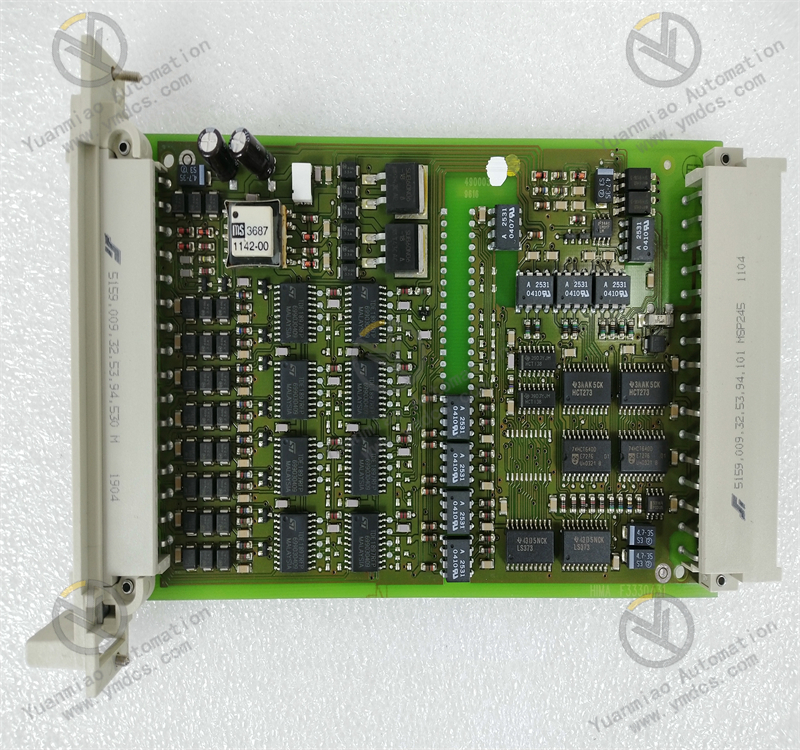

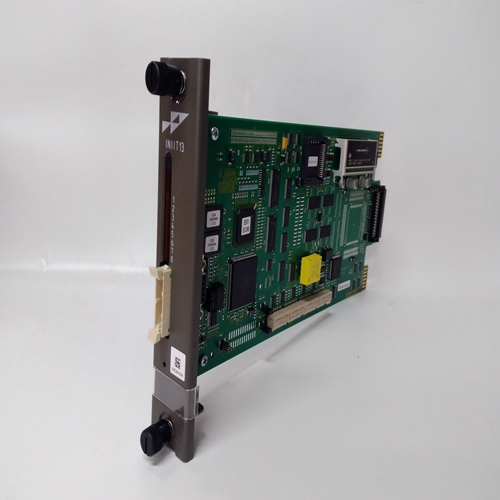

Convenient Installation and Use: With a compact design, it is easy to install on the rack of the TRICONEX system, and its connection and configuration with the system are simple, making it convenient for maintenance personnel to operate.

Manufacturing Industry: It is used for monitoring and controlling various analog quantities in the production process, such as the collection of parameters like temperature, pressure, flow rate, and liquid level, providing data support for the automated control of the production process.

Energy Industry: In the energy fields such as petroleum, natural gas, and electricity, it can collect the analog signals of field instruments to realize the monitoring and management of the energy production, transmission, and distribution processes, ensuring the stable operation of the energy system.

Chemical Industry: It is widely applied to the monitoring of various parameters in the chemical production process, helping the control system to know the production status in real time, adjust the control strategy in a timely manner, and ensure the safety and efficiency of chemical production.

Other Industrial Areas: It can also play an important role in industries such as metallurgy, papermaking, textile, and water conservancy. It is used for collecting and processing various analog signals to realize the automated control and optimization of industrial processes.

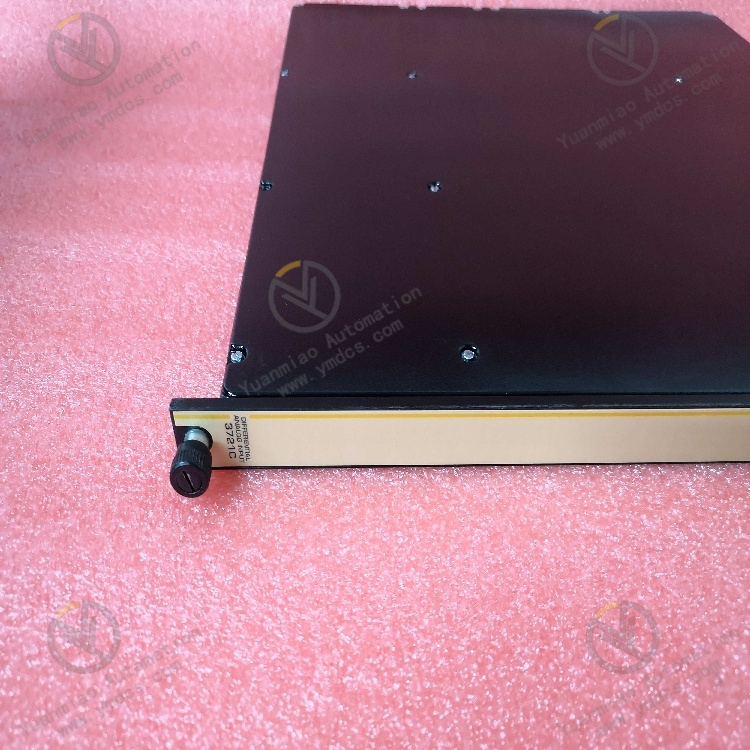

Installation Steps: Installing the Module onto the Rack Determine the Installation Location: Find a suitable slot on the rack of the TRICONEX system for installing the 3721C module. Usually, there will be clear slot numbers and markings on the rack. Select the correct slot according to the system configuration and design requirements. Insert the Module: Gently insert the TRICONEX 3721C module along the guide rails of the slot, ensuring that the pins of the module are accurately aligned with the connectors in the slot. Operate carefully during the insertion process to avoid bending or damaging the pins due to excessive force. Fix the Module: After the module is fully inserted into the slot, use a screwdriver to tighten the fixing screws on both sides of the module to firmly fix the module on the rack, preventing the module from loosening or falling off and affecting its normal operation. Connecting the Power Supply and Signal Lines Connect the Power Supply: Connect the appropriate power cable according to the power requirements of the module. Usually, the TRICONEX 3721C module requires a stable DC power input. Pay attention to the positive and negative polarities of the power supply during connection to ensure a correct connection. After the connection is completed, check whether the power connection is firm and whether there are any loose or short-circuit phenomena. Connect the Analog Input Signal Lines: Connect the analog input signal lines from field devices (such as sensors, etc.) to the corresponding terminals of the 3721C module. When connecting, make the correct wiring according to the signal type (such as 0-5VDC or -5 to +5VDC, etc.) and the wiring diagram of the module. Ensure that the signal lines are firmly connected to avoid unstable or incorrect signal transmission due to poor contact. At the same time, pay attention to the correct grounding of the shielding layer of the signal lines to reduce electromagnetic interference. Organize the Cables: After the connection of the power supply and signal lines is completed, organize and fix the cables to prevent the cables from being entangled with each other or being pulled by external forces. Tools such as cable clips and cable ties can be used to fix the cables on the rack or in the cable tray to keep the wiring neat and beautiful, and it is also convenient for subsequent maintenance and troubleshooting.

Power-on Testing

Restore the System Power Supply: After confirming that all connections are correct, gradually restore the power supply of the TRICONEX system. First, turn on the power supply of the rack, and then observe whether the power indicator light on the module lights up normally. If the power indicator light does not light up or flashes abnormally, immediately turn off the power supply and check whether there are any problems with the power connection and the module.

Check the Module Status: After the module is powered on, observe the status indicator lights on the module to understand the working status of the module. Under normal circumstances, some indicator lights (such as the operation indicator light, communication indicator light, etc.) will display according to a specific pattern. If a fault indicator light is on, refer to the user manual of the module to determine the cause of the fault and carry out the corresponding troubleshooting and handling.

Conduct Function Testing: Check whether the module can correctly collect and process signals by inputting analog signals to the module. Devices such as a signal generator can be used to generate different analog signals, and then view the output data of the module through the system's monitoring software or relevant tools to verify whether the functions of the module are normal. If abnormal data or the module cannot work properly is found, it is necessary to further check whether there are any problems with the signal line connection, module configuration, and other aspects.

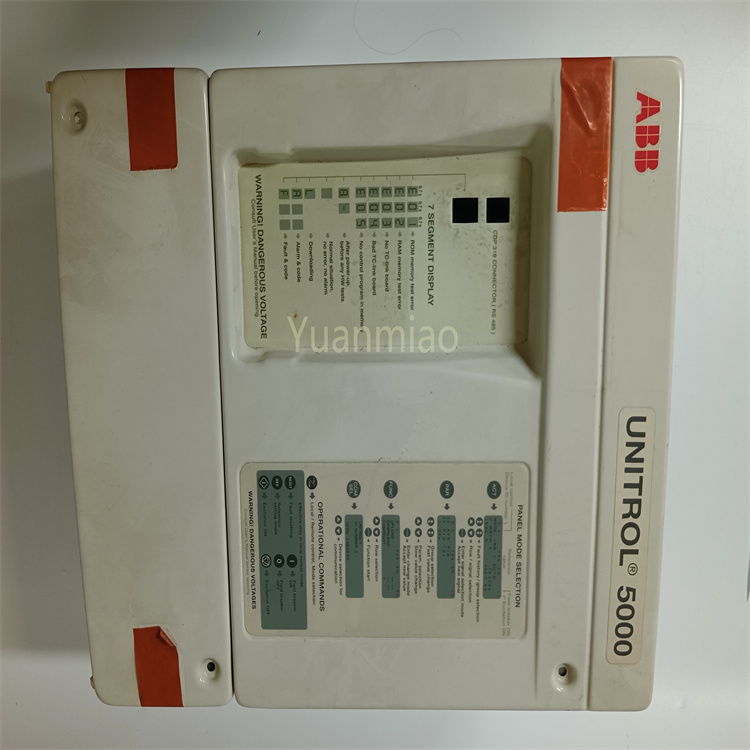

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/TRICONEX/