Description

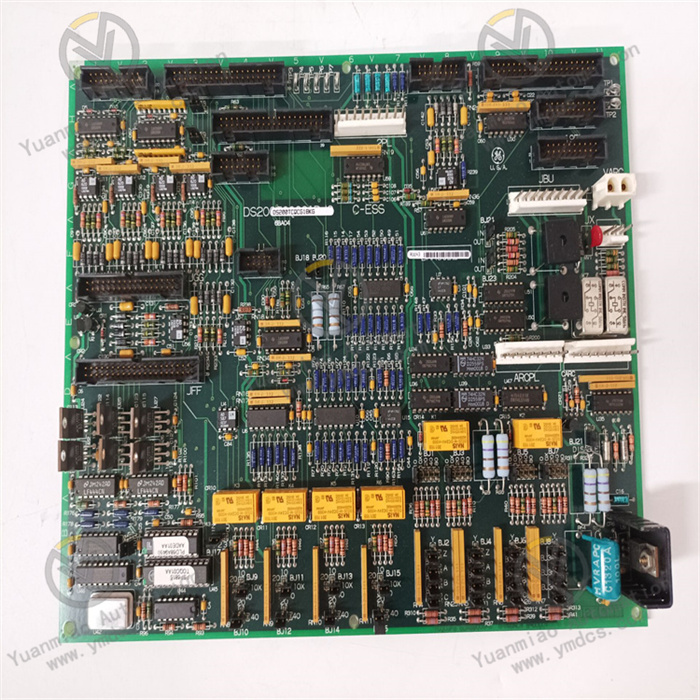

Performance Characteristics: High-performance Processor: Adopting advanced microprocessor technology, it has powerful computing power and processing speed, meeting the requirements of complex industrial control applications. Easy Programming and Configuration: It supports multiple programming languages and configuration tools, facilitating engineers to program and configure, and realizing the required control logic and functions. High-precision Control: With high-precision computing and data processing capabilities, it enables precise control of industrial equipment and processes. High Stability: By using high-quality hardware components and advanced control algorithms, it ensures high stability even in harsh industrial environments, reducing faults and downtime. Rich Interface and Communication Capabilities: It supports multiple interfaces and communication protocols, such as Profinet, EtherNet/IP, Modbus, etc., making it convenient for data exchange and communication with other devices and systems. Specification Parameters: Rated voltage is 415V, rated current is 150A, rated power is 250kW, and the operating temperature range is from -25°C to 50°C.

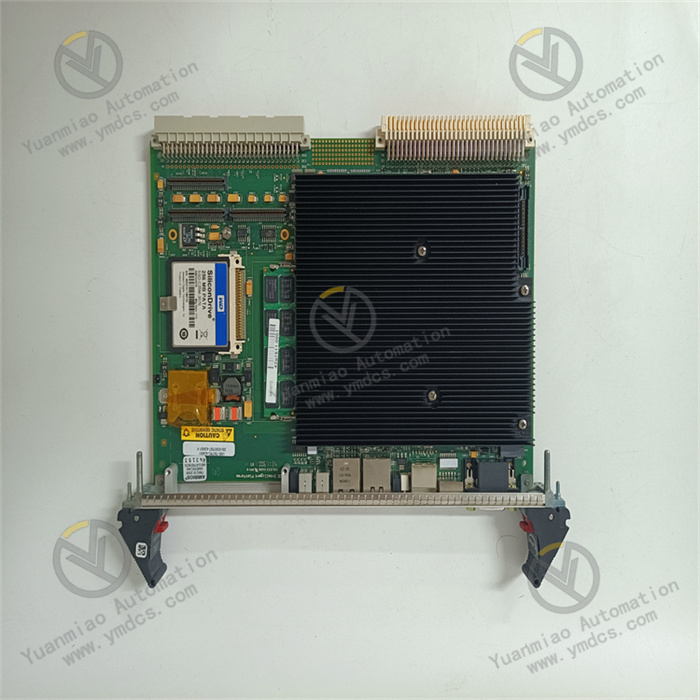

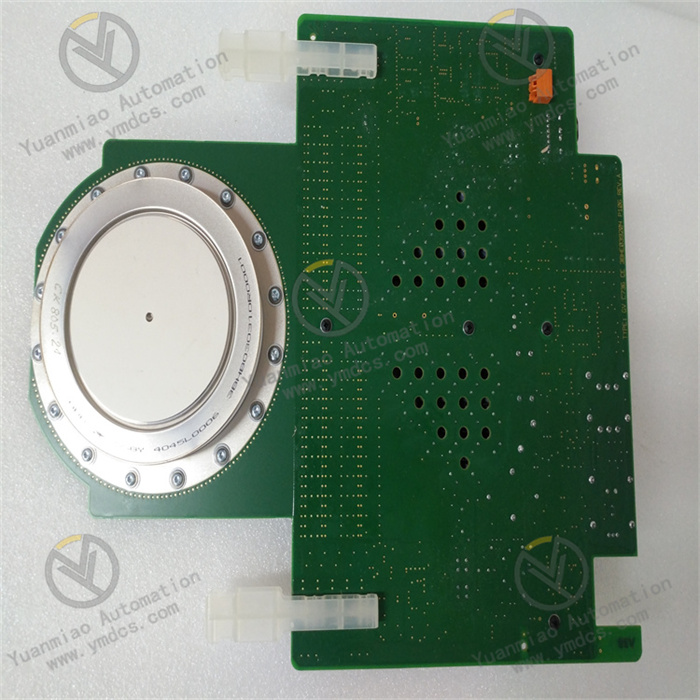

As an Integrated Gate Commutated Thyristor (IGCT) module, the installation and maintenance of ABB 3BHB030310R0001 are crucial for ensuring the normal operation of the equipment and extending its service life. The following are the detailed installation and maintenance methods: Installation Methods: 1. Preparation before Installation: Before installation, be sure to check whether the appearance of the module is damaged and whether all components are complete. At the same time, ensure that the installation environment meets the requirements of the module. For example, the ambient temperature should be between -25°C and 50°C, the relative humidity should not exceed the specified range, and the installation location should be free from severe vibration, corrosive gases, and have good ventilation conditions. 2. Electrical Connection: According to the electrical schematic diagram of the module, correctly connect the input and output cables. Ensure that the specifications of the cables match the rated current of the module, and the connections are firm and in good contact to avoid heat generation and electrical faults caused by looseness or poor contact. For the power connection, pay attention to the correct polarity to prevent damage to the module due to reverse connection. 3. Mechanical Installation: Use appropriate installation tools to fix the module on the designated installation plate or cabinet. Ensure that the installation is firm to prevent looseness due to vibration during operation. During the installation process, pay attention to the close fit between the heat dissipation surface of the module and the heat sink, and thermal conductive silicone grease can be used to improve the heat dissipation effect. 4. Cooling System Connection: If the module is equipped with a cooling system (such as a heat sink, fan, etc.), correctly connect the cooling pipeline or fan power supply. Ensure that the flow direction of the cooling liquid or cooling air is correct and there is no leakage. For air-cooled systems, ensure that the ventilation openings are unobstructed and there are no blockages. 5. Grounding Connection: To ensure the safety of the equipment and personnel, the grounding terminal of the module must be reliably grounded. The grounding resistance should comply with relevant standards and regulations, and generally, the grounding resistance is required to be less than 4 ohms.

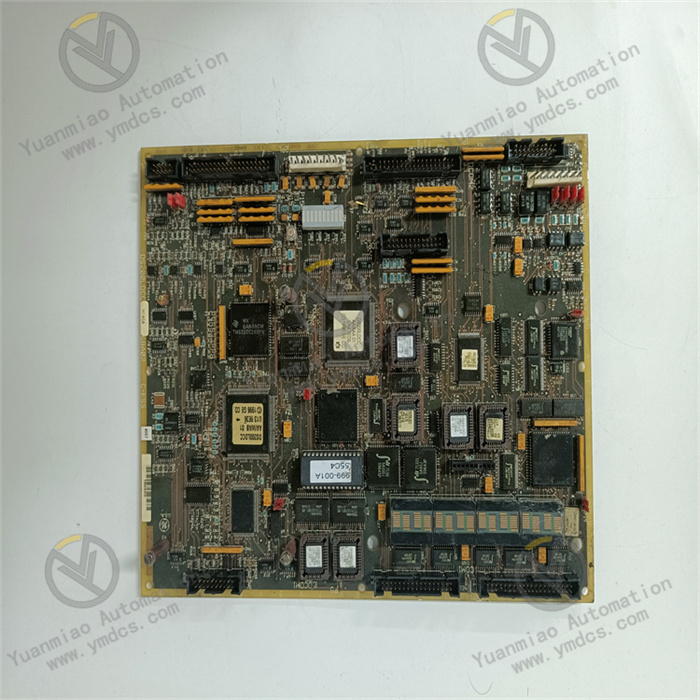

Maintenance Methods: 1. Regular Inspection: Regularly conduct an appearance inspection of the module to check for any obvious signs of damage, deformation, or overheating. Check whether the electrical connection parts are loose and whether the cables are damaged or aged. At the same time, check whether the cooling system is operating normally, such as whether the fan is running properly and whether there is any leakage of the cooling liquid. 2. Cleaning and Maintenance: Regularly clean the surface and heat sink of the module to remove dust and dirt to maintain good heat dissipation performance. For air-cooled modules, regularly clean the sundries in the ventilation openings to ensure smooth ventilation. When cleaning, use a dry soft cloth or compressed air, and avoid using wet cloths or corrosive cleaning agents. 3. Electrical Performance Testing: Regularly test the electrical performance of the module, such as measuring the input and output voltages and currents, and checking the insulation resistance of the module. If any abnormal electrical performance is found, timely analyze and deal with it.

4. Replacement of Vulnerable Parts: For vulnerable parts in the module (such as fans, capacitors, etc.), they should be replaced regularly according to their service life and actual operation conditions. When replacing vulnerable parts, ensure that the specifications and models of the new parts are the same as the original ones, and replace them according to the correct installation method.

5. Software Update: If the module supports software updates, promptly pay attention to the software version information released by ABB officially and perform software updates as needed. Software updates can fix known problems and improve the performance and stability of the module.

6. Fault Handling: If the module malfunctions, stop the operation immediately and troubleshoot and handle the fault according to the fault diagnosis manual provided by ABB. When handling faults, pay attention to safety and avoid electric shock or other accidental injuries.