Description

2.3 PLC features and functions

(1) the main characteristics of PLC. PLC is characterized by reliable work, fast running speed, building block structure, flexible combination, good compatibility, simple programming and generation, rich, strong network function.

(2) the main functions of PLC. PLC system can complete the industrial real-time sequence control, condition control, counting control, step control and other functions; Capable of modular/digital (A/D), digital/modular (D/A) conversion, data processing, communication networking, real-time monitoring and other functions. Years of practice shows that PLC, reliable, is specially designed for the factory, with according to the requirements of the working environment reinforcement components, real-time scanning practice and fault diagnosis function, simple troubleshooting, deep preference of users. What makes a PLC so reliable is a real-time core or operating system of executable relay logic, sequential function diagrams, function blocks, structural text, command directories, or a combination of them. In the event of failure, the built-in device can maintain mechanical damage, and can maintain an orderly, predictable sequence.

2.4 PLC development trend: very fast logic operation and logic control, sequence control ability, in the discrete control of some reliability, convenient and easy to learn the programming method, so that it has an indisputable position in the discrete industrial automation field.

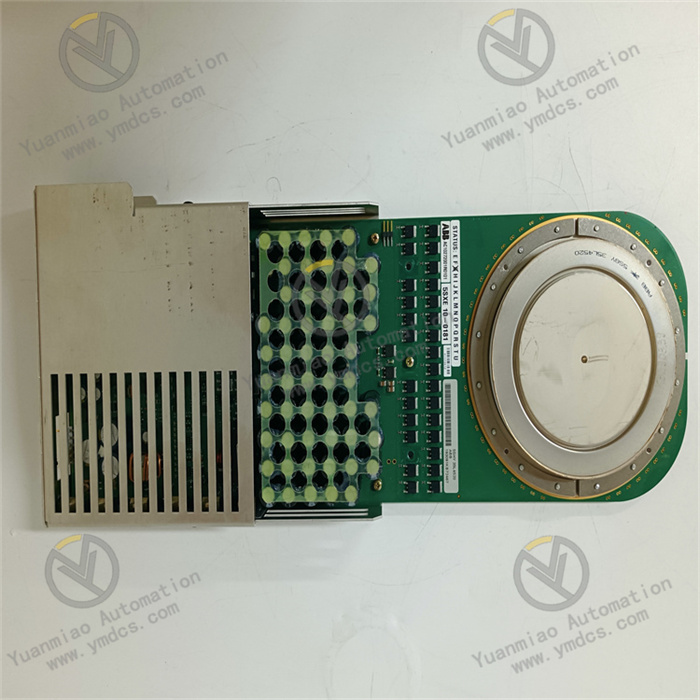

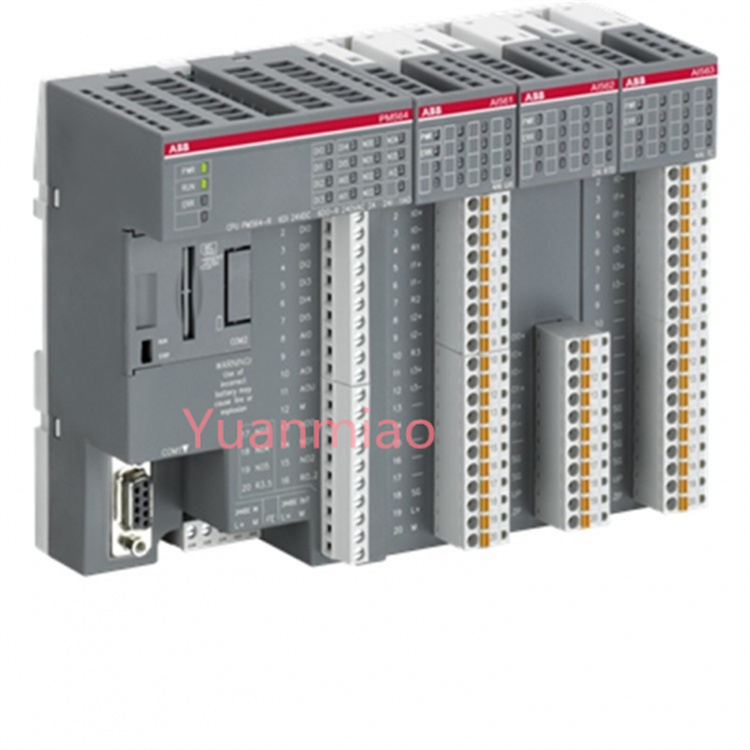

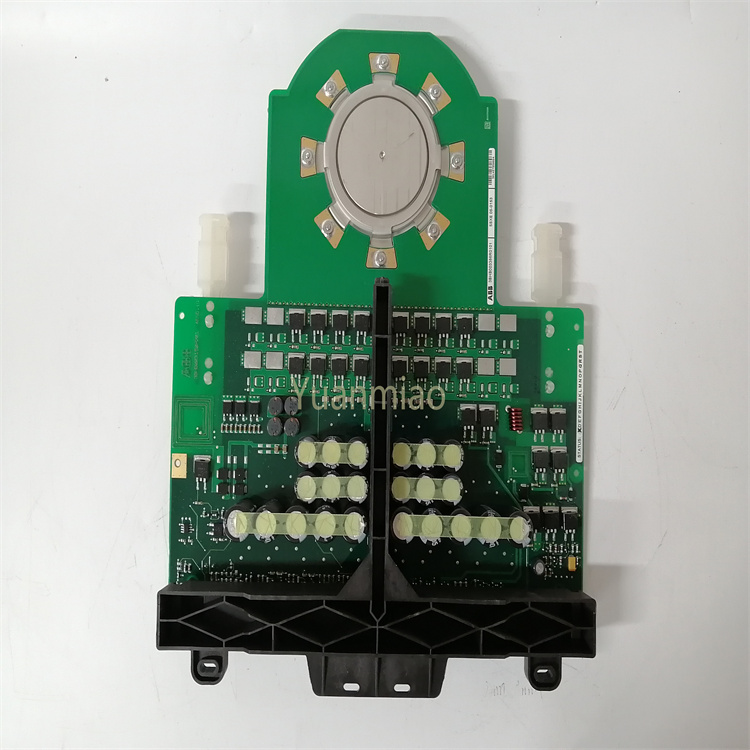

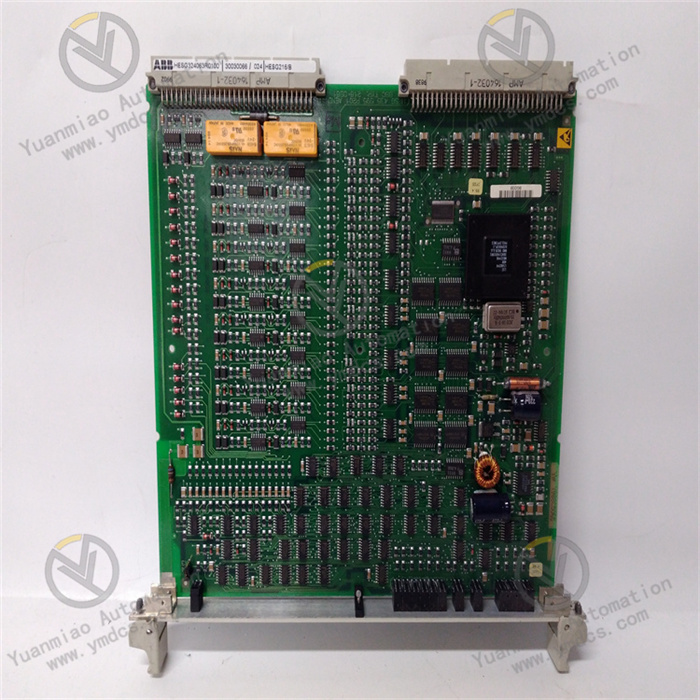

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

The United States, Germany, France, Italy and other European Union industrial control products, spare parts

In order to ensure safety production and realize emergency treatment of emergency accidents, the external automatic tracking regulator is installed on the six regulator circuits. In case of control system failure, the tracking regulator is automatically switched to control the regulating valve independently of DCS; 21 main valves are equipped with emergency treatment button, which is independent of DCS to realize forced switch on the valve. 2.3. hardware configuration:

Omron C200 PLC is selected in the control station, and 9 digital modules (od211/ id212), 4 analog modules (ad003) and 3 regulating modules (pid03) are configured; The operation station adopts Dell opt gx150 computer; The engineer station adopts compa PC. The composition is as follows:

2.4. software configuration of control station:

The configuration of control station is based on the system software SSS of OMRON as the technical platform and ladder diagram as programming tool. The configuration contents are as follows:

2.4.1.allocation of PLC internal address:

I/o address distribution: the i/o address of PLC is the only one-to-one register address for data communication between PLC and field detection equipment and actuator. The allocation of i/o address is the basis for further configuration of PLC; For omron-c200, i/o address is related to the connected i/o module; The i/o address of the field equipment connected to the digital module depends on the installation position and the point number on the module. The i/o address of the field equipment connected to the analog module and PID module depends on the unit number of the i/o module (different modules shall be set with different unit numbers through the hard opening and closing of the module) and the point number on the module; For example, in the configuration of this system, the analog signal of 4-20mA output by the radar level transmitter LT-101 on site is connected to the second point of analog input module ad003 with unit number 3, the address of its configuration in PLC is ir:132; When the closed signal of valve hv120 is connected to the tenth point of the digital input module id212 installed in the second slot of the expansion rack, its configuration address in PLC is ir:01210; In this system, 142 i/o addresses are defined.